February 16th 2023

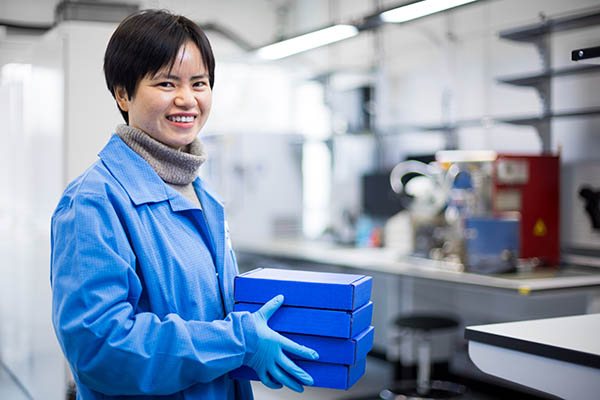

Having already offered 3D printing of microlenses on fiber arrays and photonic integrated circuits (PICs) as part of a partnership with Nanoscribe, photonics packaging foundry PHIX is preparing to further industrialize this process by acquiring a dedicated machine for their facility. As the new 3D microfabrication expert at PHIX, design engineer Chunting Zhong explains how she has been working towards a smooth technology transfer.

3D microfabrication based on Two-Photon Polymerization

In very close proximity to the Nanoscribe headquarters in Germany, Chunting acquired her PhD in Chemistry at the Karlsruhe Institute of Technology (KIT). “During my research I already discovered the potential of Two-Photon Polymerization (2PP), which is the technological basis for the Nanoscribe product line of microfabrication machine tools”, says Chunting. “Having seen the powerful applications in integrated photonics packaging, I’m looking forward to introduce the process at the PHIX facility”.

Nanoscribe’s Quantum X align 3D printer allows the construction of tiny freeform micro-optics at a submicron positioning accuracy. Using this machine PHIX has already successfully introduced lensed fiber arrays into their offering and demonstrated the ability to print microlens arrays onto PICs. These print jobs are currently carried out on equipment at Nanoscribe, with Chunting taking on the role of project leader for PHIX. This microfabrication technology also opens up possibilities for printing non-optical structures, such as for microfluidics or MEMS applications. This success and commercial potential made PHIX decide to purchase their own Quantum X align system, to be deployed by the end of 2023.

Process transfer for industrial scale-up of microlens printing

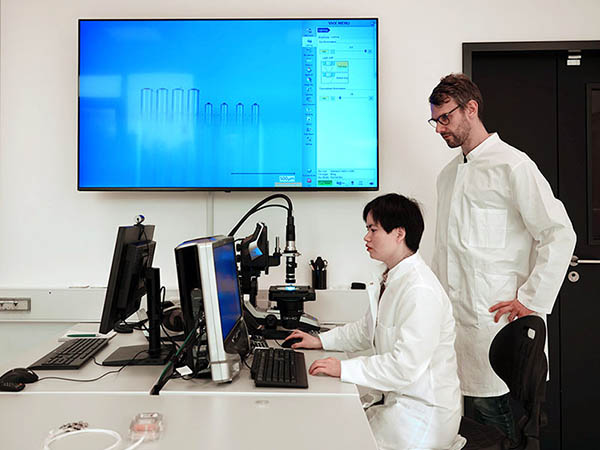

In anticipation of the arrival of the machine, Chunting is receiving training at Nanoscribe. Here, she practices the workflow of choosing lens designs, creating printing jobs, and transferring these to the machine. “We’re also covering a number of analysis and testing techniques, including microscopy and confocal measurement”, Chunting adds. “These techniques, and possibly additional ones, are required when we start running the process on a more industrial scale, so I’m looking to make these available at PHIX as well”. The industrial application of the 3D microfabrication process by PHIX provides Nanoscribe with valuable feedback on market requirements and a great testimony of the power of the Quantum X Align platform.

“This early onboarding process and our ongoing cooperation for the Photonics Packaging and Assembly Service are providing a mutual benefit for PHIX and Nanoscribe. We jointly develop and validate tools and processes all dedicated to photonics packaging.”

Jörg Smolenski

Nanoscribe Business Development Manager

The timely addition of Chunting to the PHIX team is giving her the opportunity to receive training, become a product owner, and prepare the facility for the introduction of the innovative microfabrication process. This ensures that when the machine arrives, PHIX will be able to start production very quickly. Chunting is looking forward to this moment. “Apart from serving our own integrated photonics packaging activities, having this process in-house will strengthen PHIX’s capabilities as a microfabrication job shop for a wide variety of industrial customers”, she concludes.

“Apart from serving our own integrated photonics packaging activities, having this process in-house will strengthen PHIX’s capabilities as a microfabrication job shop for a wide variety of industrial customers.”

Chunting Zhong

PHIX Design Engineer

Discover lensed fiber arrays at PHIX

Explore PHIX’s current offering of lensed fiber arrays (LFAs), suitable for free space coupling to other optical components like photonic integrated circuits (PICs). The microlenses are 3D printed and aligned with submicron precision to the fiber cores using Nanoscribe’s Quantum X Align system. They can focus or collimate the light from the fibers, enabling mode field conversion or coupling over distances up to 100 μm. Periscopic lenses suitable for wafer level testing of PICs are also available.