Our offering

PHIX Photonics Assembly is an independent packaging foundry for integrated photonics. We are an OEM supplier of optoelectronic modules and components in scalable manufacturing volumes. Our processes are also available for contract manufacturing, where our customers outsource or second-source production steps to us.

With our highly skilled engineering team and our international partnerships we provide solutions on a global scale, offering a one-stop shop for your packaging requirements.

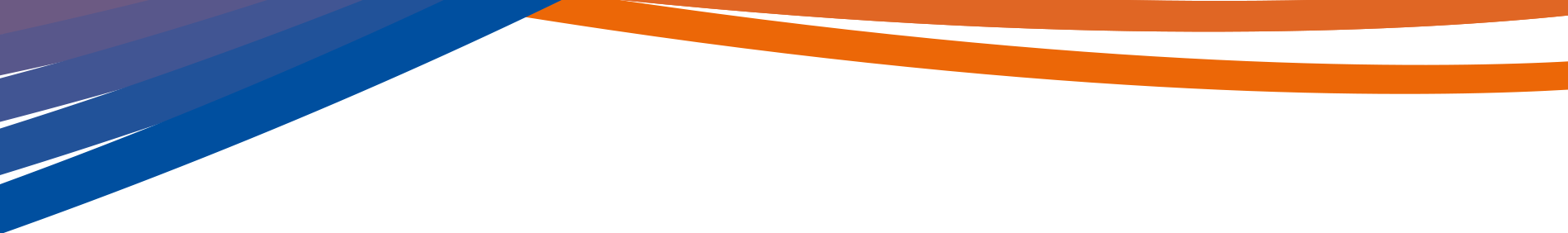

Prototype Package

PHIX has developed several packaging solutions that allow for convenient, quick and affordable prototyping of your first photonic integrated circuits (PICs). They provide a housing with electrical connections, optical interfaces, and thermal management. Hybrid assembly of auxiliary chips is also supported. Each of our standard housings have characteristics that favor certain chip dimensions and system configurations. However, if you have special requirements, we are happy to design a customized prototype package for you.

Volume Package

If you want to introduce your product into a specific market, we are there to help you with our custom design competencies. We have a broad experience in designing and assembling modules for telecommunications, industrial, automotive, medical, space and military applications. We support all major material platforms, such as SiN, InP, LiNbO3 and GaAs, and can even co-package multiple PIC technologies into one product. By collaborating in an early stage of the product development, we can make sure that your product is suitable for a scale-up to high volume manufacturing.

Contract Manufacturing

If you want to outsource your assembly process or you’re looking for a secondary supplier to your own manufacturing, we are your trusted partner and scale up with your growth. Our engineering team can validate what is required for a safe launch transfer and decide together how to release our packaging foundry for your product.

We’re happy to support you by performing dedicated steps of your production on our equipment. Here we offer services for wafer dicing, die bonding, wire bonding, hybrid assembly, fiber attachment, testing, etc.

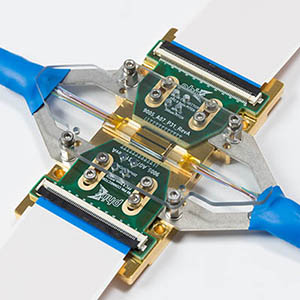

Fiber Arrays

PHIX manufactures high performance standard and custom v-groove fiber arrays with sub-micron fiber spacing accuracy and uniform fiber core center line. Our PM type v-groove fiber array has a very precise axis alignment and high extinction ratio, while our multi-mode fiber array can be made with a variety of fibers including non-fluorescent, UV fibers, and Mid-IR fibers.

We have a suite of standard fiber arrays available from stock.

We now have a dedicated fiber array webshop where you can order quickly from stock!

Fiber array with Spot Size Converter

In order to efficiently couple light from Photonic Integrated Circuits (PICs) with small mode field diameters, one needs to taper down the light in order to efficiently couple it to a glass fiber. PHIX offers Spot Size Converters (SSC) that are pre-terminated on a fiber array. This way a direct connection can be made to your PIC without the requirement to keep it at a specific focus distance in front of your chip. This reduces the required alignment degrees of freedom and ensures quick and repeatable interfacing. Discover what our ion exchanged glass (IONext) and silicon nitride (SiN) spot size converter platforms can offer.

Lensed fiber array

Our lensed fiber arrays (LFAs) are v-groove optical fiber arrays with 3D printed lenses at the ends of the fibers. They are intended for free space coupling to other fiber arrays, photonic integrated circuits (PICs), or other components. The 3D printed microlenses can focus or collimate the light from the fibers, enabling mode field conversion or coupling over larger distances. This product is made possible by a collaboration with our microfabrication partner Nanoscribe.

“For more than a decade, our company has been providing PIC feasibility studies, design and development, focusing on quality and clear project outcomes. PHIX has been a valued, reliable and interactive partner in realizing our wishes in a range of challenging packaging projects with excellent results.” – Ronald Broeke (Bright Photonics)