September 17th 2025

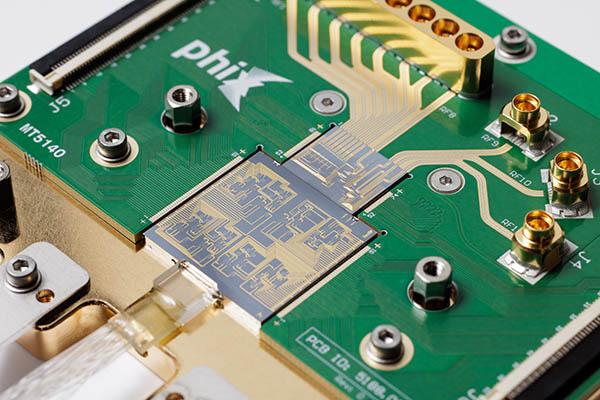

Designing and manufacturing a photonic integrated circuit (PIC)–based optoelectronic module is a symbiosis of various disciplines, where success lies in bringing PIC design, module architecture, process development, and manufacturing into harmony. This blog series helps PIC designers take a proactive and system-level approach, with an early consideration of device manufacturability. This instalment shows how power budgeting can balance device performance targets with cost considerations and ease of scaleup to volume production.

Benefits of a system-level approach to PIC design

PIC designers often underestimate the importance of their early design and layout choices to the performance, cost, manufacturability, and time to market of the finished optoelectronic module. Designing with module architecture and (volume) manufacturing in mind can go a long way in controlling the notoriously sizeable packaging costs, while ensuring solid product performance.

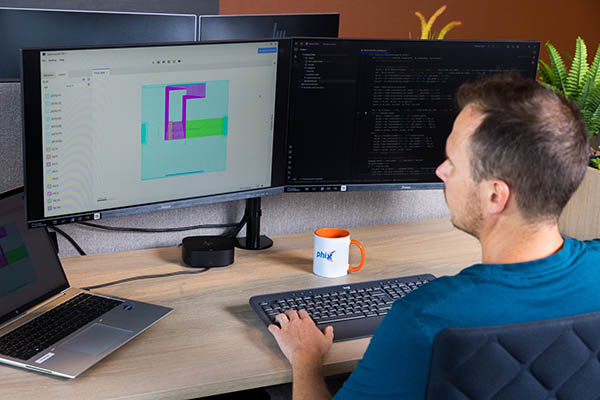

By studying this blog series, in combination with our comprehensive PIC Design Guidelines document, you will adopt an eagle-eye view that reveals the full playing field of integrated photonics packaging. Learning to identify and balance all the relevant design parameters is crucial for bringing your innovation from a lab-scale prototype to scalable industrial production.

In earlier blogs we covered the importance of mode field matching and using waveguide alignment loops. Today, we will show how you can benefit from mapping the power budget of your device and adding some extra margin to ease manufacturing.

What is power budgeting?

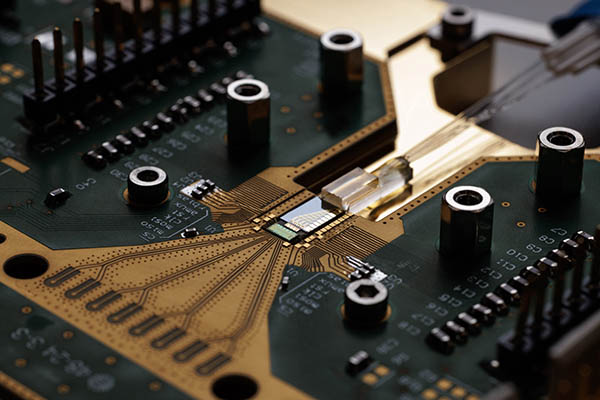

In the design and manufacturing of an optoelectronic module it is impossible to avoid introducing small losses in many places in the device, starting at the optical structures on the chip and moving through all the components and interfaces, such as optical fiber attachments, chip-to-chip interconnects, free space gaps, and connectors. These losses will attenuate the optical power generated by the source. Power budgeting means considering the expected losses in each component and interface, making sure that sufficient optical power remains for detecting the photons providing the module’s intended functionality and performance. If the power budget is negative, this can be resolved by choosing a light source that provides more light, reducing the losses in the link, or using enhanced detection methods that provide higher sensitivity levels.

Designing with margin

Having made sure that the total expected losses don’t attenuate the available power below the required minimum, it’s important to uphold a certain safety margin. Among other things, this margin accounts for variations in system temperature and degradation of light sources. However, it is highly beneficial to consider an additional power budget margin, which can have an impact on the cost and manufacturability of the module.

As a world leading integrated photonics packaging contract manufacturer, PHIX can achieve high optical alignment accuracies and therefore support very low coupling losses, using high-quality building blocks, specialized processes, and state-of-the-art equipment. However, driving these losses to an absolute minimum can add considerable cost and complexity to the device assembly.

In certain application areas, such as quantum technologies or astrophotonics, every (milli)decibel of loss is critical, and production volumes are typically low. In these cases, investing in the absolute lowest-loss components and interfaces might be justified.

But for applications intended to scale to high volumes, the calculus changes. Here, it is essential to design with additional margin in the power budget. By allowing for production tolerances, designers give the packaging foundry more flexibility to optimize for manufacturability, cost-effectiveness and yield, rather than being forced to prioritize maximum performance at all costs. The enhanced cycle times resulting from these increased production tolerances will raise productivity and reduce equipment investments during the manufacturing scaleup.

A well-considered power budget margin, therefore, provides the breathing room needed to move from low-volume prototyping into automated, high-volume manufacturing without compromising on yield or driving costs too high.

How PHIX makes your projects succeed

Power budgeting is just one of many design practices that support manufacturability and scalability. Factors such as mode field matching, PIC layout, and bill of materials optimization, for example, also play important roles.

The common thread is that these considerations are best addressed early in the design process. Engaging with PHIX at the outset gives PIC designers access to world-leading expertise in balancing performance, yield, cost, and scalability. Our early collaboration will help ensure that promising photonic technologies don’t get stuck at the prototype stage but can make the leap to becoming robust, manufacturable products!

Download our Design Guidelines (.pdf)

To help you optimize your PIC design for low-cost and low-risk packaging and select the most suitable standardized package type, we offer you our PHIX Design Guidelines document as a free download.